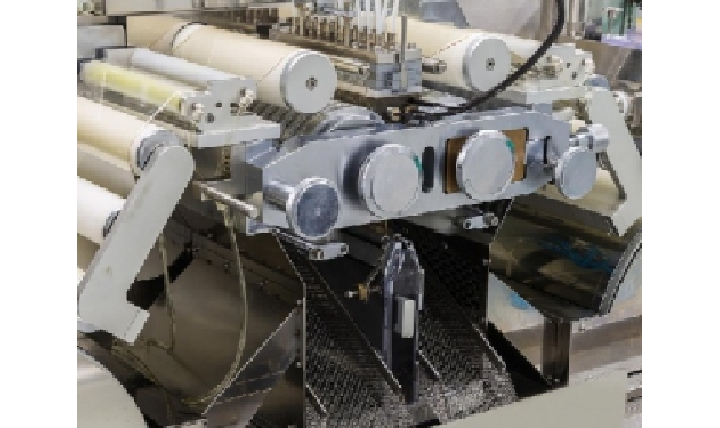

New technology to be for the roller industry in the future

New technology to be for the roller industry in the future

As we head into the future, there are several technological advancements that are set to disrupt the roller industry. These innovations will have a significant impact on the way that rollers are manufactured, used, and maintained. In this chapter, we will explore some of these new technologies and the ways in which they will transform the industry.

Advanced Materials: One of the most significant trends in the roller industry is the development of new materials. These advanced materials will offer several advantages over traditional materials, including improved strength, durability, and performance.

Smart Rollers: Another major trend in the roller industry is the development of smart rollers. These rollers will be equipped with sensors and other advanced technologies that will allow them to monitor their own performance, detect faults, and communicate with other machines in the production line. Smart rollers will also be able to adjust their own parameters based on the material being processed, resulting in higher efficiency and lower waste. The global market for smart sensors is expected to grow at a CAGR of 19.2% from 2020 to 2025, according to Mordor Intelligence.

Automation: Automation is already transforming the roller industry, and this trend is expected to continue into the future. Automated systems will be able to handle tasks that are currently performed manually, such as loading and unloading rollers, adjusting roller parameters, and monitoring the production line. This will result in increased productivity, lower costs, and reduced downtime. The global market for industrial automation is expected to reach $326.14 billion by 2027, growing at a CAGR of 8.9% from 2020 to 2027, according to Allied Market Research.

3D Printing: 3D printing is another technology that is set to revolutionize the roller industry. With 3D printing, it will be possible to manufacture custom rollers quickly and at a low cost. This will allow manufacturers to produce rollers that are tailored to specific applications, resulting in higher performance and lower costs. According to a report by Wohlers Associates, the global market for 3D printing is expected to reach $35.6 billion by 2024, growing at a CAGR of 23.5%.

Artificial Intelligence: Artificial intelligence (AI) is already being used in several industries, and the roller industry is no exception. AI algorithms can be used to optimize roller performance, detect faults, and predict maintenance needs. This will result in increased efficiency, lower downtime, and reduced costs. According to a report by Grand View Research, the global market for artificial intelligence is expected to reach $390.9 billion by 2025, growing at a CAGR of 46.2%.

In conclusion, the roller industry is set to undergo significant transformation in the coming years, thanks to the development of new technologies such as advanced materials, smart rollers, automation, 3D printing, and artificial intelligence. These technologies will offer several benefits, including increased efficiency, lower costs, and improved performance. Manufacturers who embrace these innovations will be well-positioned to succeed in the future roller industry market.